380V 3-Phase Induction Heating Machine For Welding Fabrication

Quick Detail:

Type:Other

Place of Origin:China (Mainland)

Brand Name:Canroon

Model Number:CR2000-080A-14T

Voltage:380V

Current:122A

Rated Capacity:80KW

Rated Duty Cycle:80KW

Dimensions:880*663*982

Weight:201Kg

Usage:induction temperature stress relievers

Certification:CE ISO9001:2008

After-sales Service Provided:Overseas service center available

Process:Induction heating equipment

Input Power:380V,3-Phase

Temperature recorder:6 Channel temperature recorder

Description:

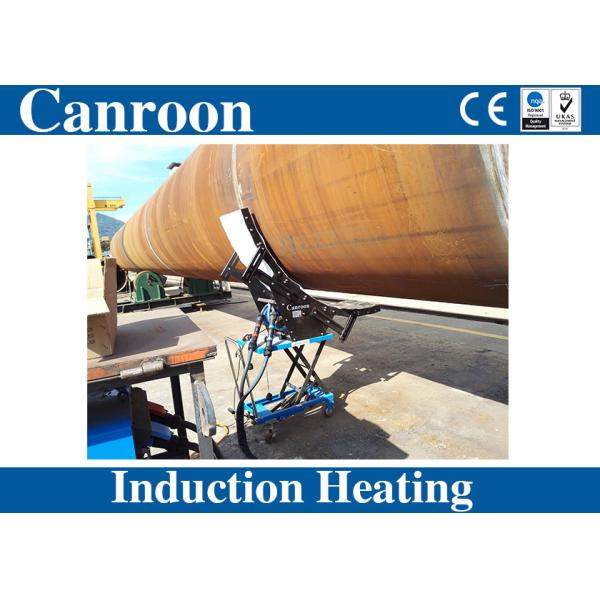

The CR2000 induction preheater is an advanced air-cooled heating

system designed for welding preheat and industrial fabrication.

Capable of reaching temperatures up to 1450°F, it delivers rapid

and uniform heating through multiple output channels and six

control thermocouples. Compared with conventional heating methods,

the CR2000 achieves significantly faster heat-up times and higher

process efficiency.

The system features an intuitive operator interface that supports

programmable ramp-up and hold cycles, enabling precise temperature

control for various applications. It also provides guided operation

to help users maximize coil performance and ensure consistent

heating quality across different workpieces.

Applications:

With the introduction of theInduction Heating Machine, this simple

and cost-effective heating process can be applied in the following

applications to deliver fast and consistent heat:

- Welding fabrication and construction;

- Preheating of welds;

- Post-weld heat treatment;

- Coating removal;

- Shrink Fit and so on

Specifications:

Input Amperes at Rated Output | 380V:122A |

Thermal conversion efficiency | More than 90% |

Maximum Rated output | 80KW |

Cooling Mode | Air cooled |

Input Power | 380V 3-Phase,50HZ |

Rated Output | 80KW at 100% duty cycle,1-35KHZ |

TC input | 6 circuit |

Digital Recorder | Optional |

Control Model | Digital Control |

Resonance | Series Resonance |

Temperature | Max 1450°F |

Dimensions | H:880MM W:663MM D:982MM |

Transportation | By sea or By Air |

Weight | 201KG |

Warranty | 12 Months |

Competitive Advantage:

Operational Flexibility That Drives Revenue: Optional mobile gear enables seamless deployment across welding,

fabrication, and maintenance projects—keeping your teams productive

and your workflow uninterrupted.

Smart Temperature Intelligence for Zero-Error Heating: Automated, guided programming ensures precise temperature

execution, reducing operator learning time and improving output

quality.

Data-Driven Thermal Precision: Multiple thermocouple inputs deliver real-time insights and active

temperature correction, ensuring consistent results across every

job.

Quality Enhancement That Reduces Rework Costs: Uniform heat penetration strengthens weld integrity, minimizes

defects, and lowers your total cost of quality.

Enterprise-Grade Safety Architecture: Built-in output detection and isolation fault protection safeguard

operations, preventing costly downtime.

OPEX-Friendly Heating Solution: No fuel consumption, ultra-low insulation costs, and highly

reusable materials significantly reduce long-term operational

spending.

Material-Protective Heating Process: Internal induction heating eliminates surface damage, reducing

scrap rates and extending material life.

Accelerated Time-to-Heat for Faster Turnaround: Rapid heating cycles shorten project timelines and increase

equipment utilization rates.

Cleaner, Safer, More Compliant Worksites: No open flames, no gas cylinders—supporting safer operations and

easier compliance with site safety regulations.

High-Efficiency Energy Conversion: Over 90% efficiency delivers more usable energy to the part,

lowering electricity costs while raising throughput.

Rapid Deployment, Immediate Productivity: Flexible blankets and intuitive controls allow teams to set up

fast and start generating value right away.

Tag:Induction Heating